Are you tired of going to different places and systems to look for data on the machines in your plant? You can get all that information in one place with LubePM Data Manager. In this video, Travis shares how LubePM Data Manager houses multiple types of data, including: oil maintenance make and model lubricant analysis hardware sizes environmental conditions and more!

Simplifying Machine Data Management with LubePM’s Data Manager

Introduction

In the world of industrial maintenance, having quick and easy access to vital machine data is crucial for optimizing operations and ensuring equipment longevity. Traditionally, this requires jumping from one system to another, searching for information on different machines, and dealing with scattered data. But what if a solution could centralize all the essential data in one place? In this blog post, we’ll explore the LubePM Data Manager — a tool designed to simplify machine data management, making your maintenance tasks more efficient and effective.

The Pain Points

Maintenance and lubrication technicians share a common frustration of navigating through multiple systems to collect data on various machines within a plant. This inefficiency is something that many maintenance professionals can understand, as it often results in wasted time and resources. Fortunately, LubePM’s Data Manager can streamline this process and make data access more convenient.

LubePM Data Manager: Your All-in-One Solution

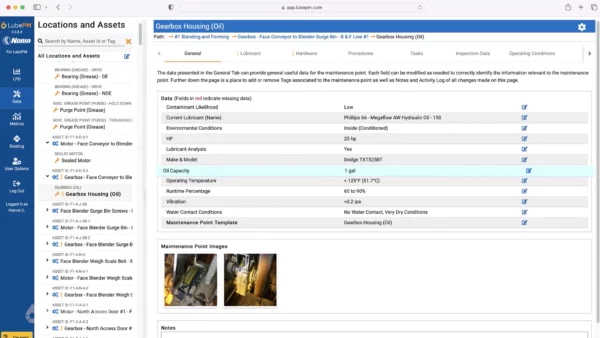

Maintenance teams frequently encounter the challenge of collecting diverse data points from their machines. These data points include essential information like the make and model of the machines, as well as technical details such as the volume of lubricant needed. This crucial data can now be consolidated and stored in the LubePM Data Manager.

Make, Model, and Volume – All in One Place

The LubePM Data Manager houses a comprehensive database containing not only the make and model of the machines but also critical data like oil-volume requirements. This centralized repository simplifies accessing this information, saving time and reducing the chance of errors.

Hardware Details

In addition to make, model and volume, the Data Manager provides a home for other essential hardware details — including site glass sizes, level plug sizes and bottom port sizes. This feature ensures that maintenance teams can access all the data they need for each machine, promoting efficient and accurate maintenance activities.

Environmental Data Matters

Capturing and storing environmental data of machines is also critical. This includes whether the machine is in a wet, dry or dusty environment. These factors have a significant impact on maintenance schedules and calculations. By housing this information in the Data Manager, LubePM provides a holistic view of each machine’s operating conditions, allowing for more informed maintenance planning.

Conclusion

LubePM’s Data Manager is a game-changer for maintenance professionals. It centralizes critical machine data — making it more accessible and efficient, and provides a holistic view of environmental conditions. Discover why leading experts trust LubePM to manage their lubrication program. To learn more and request a LubePM demo, go to: https://lubepm.com/#contact